Taa, anyị na-atụle electro-spark deposition's apply in metal alloys , n'otu oge ahụ anyị ga-elekwasị anya na nkà na ụzụ a otú e si gbanwee ebu na injection ịkpụzi tooling na nkedo ebu.

Kedu ihe bụ Electro-Spark Deposition?

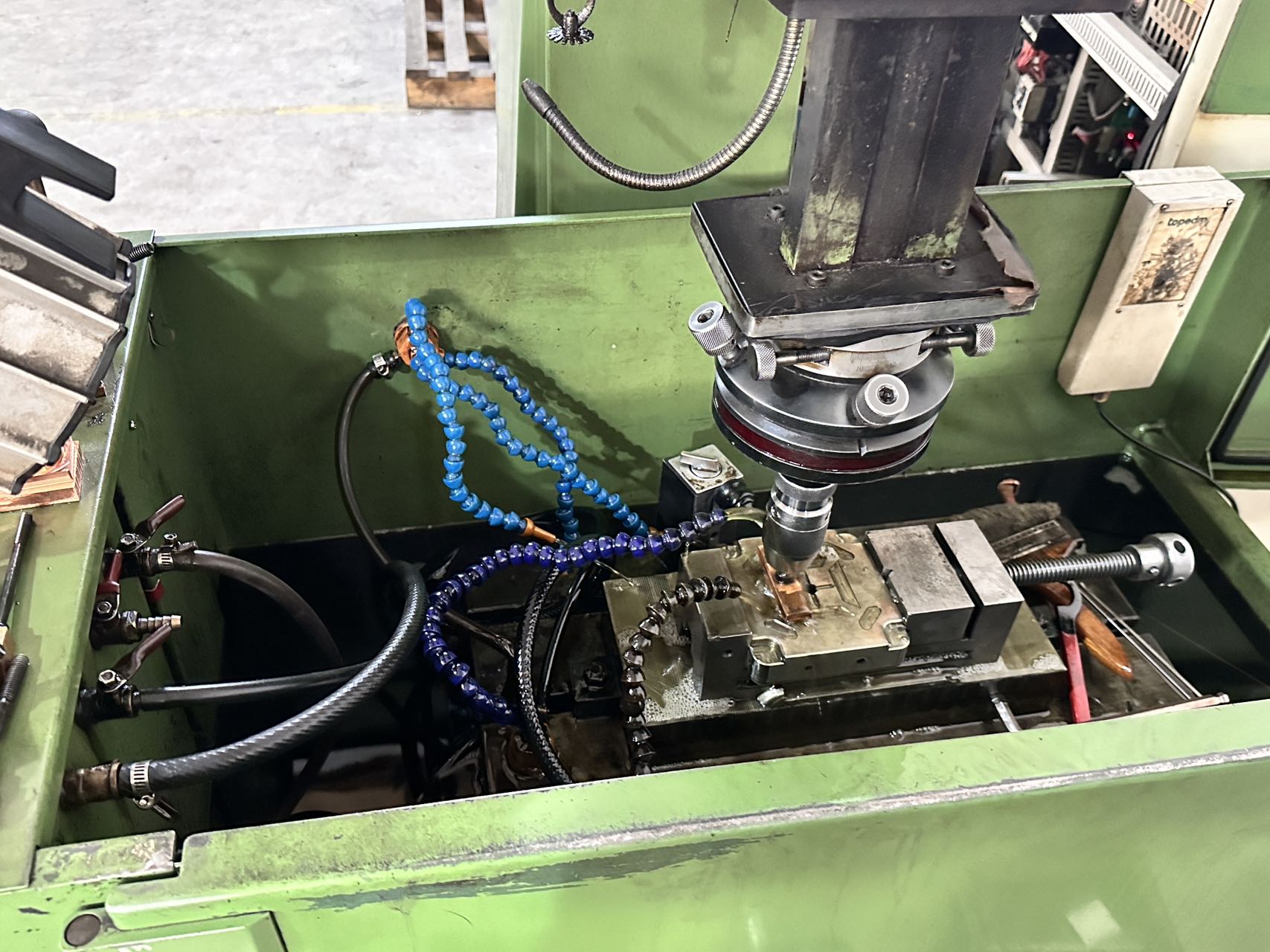

Ngwọta electro-spark, nke a makwaara dị ka Electro-discharge machining (EDM), bụ usoro nrụpụta pụrụ iche nke gụnyere iji mpụta eletrik na-emepụta ma gbanwee elu akụkụ igwe.

N'oge ọgwụgwọ Electro-spark, a na-emepụta mwepu eletrik n'etiti electrode na workpiece, nke a na-ejikarị eme ihe dị ka ígwè ma ọ bụ alloys.Usoro ahụ na-amalite site n'itinye electrode ahụ, mgbe mgbe n'ụdị obere ngwá ọrụ dị n'ụdị, dị nso na workpiece.

Mgbe a na-etinye voltaji n'etiti electrode na workpiece, a na-eme usoro nke ọkụ eletrik ngwa ngwa.Mwepu ndị a na-emepụta okpomọkụ siri ike, na-agbaze obere akụkụ nke elu ọrụ ahụ.Mmiri dielectric na-emenyụ ígwè ahụ a wụrụ awụ ngwa ngwa, na-eme ka ọ gbasie ike wee ghọọ obere oghere ma ọ bụ mgbawa.

ESD etinyere na metal alloys

Mgbe a tọhapụrụ ike capacitor, ihe dị ugbu a na-emepụta arc plasma dị elu n'etiti ọnụ electrode na metal alloy workpiece.Ọnọdụ okpomọkụ a dị elu dị n'etiti 8000 na 25000 Celsius.Plasma arc ionizes anode na-ebufe ngwa ngwa ihe wụrụ awụ na workpiece.

A na-ebufe anode ionizing a na mkpụrụ site na mkpirisi mkpirisi.Arc na-ekpo ọkụ dị elu nwere ihe ndị bụ anode, iyi ọkụ (jet na-ekpo ọkụ), na plasma mepụtara site na mwepu nke gas na atom ndị na-arụ ọrụ nke nitrogen, oxygen, na carbon.Ọtụtụ n'ime okpomọkụ na-ebu site thermal jet na plasma.

N'ihi na pulses dị mkpụmkpụ, ịnyefe okpomọkụ site na jet thermal na gas ndị ọzọ dị ntakịrị, na naanị okpomọkụ na-ebufe na mkpụrụ bụ site na ọnụ ọgụgụ dị nta nke anode nke etinyere na mkpụrụ.Ya mere, pulses ndị a na-ebufe obere okpomọkụ na mkpụrụ na-enweghị ịgbanwe microstructure nke mkpụrụ.Usoro a bara uru karịa usoro ịgbado ọkụ nke a na-ejikarị na-arụkwa alloys na mpaghara mpaghara okpomọkụ na-emetụta adịghị mma (dịka ọmụmaatụ, ike siri ike, isi ike dị elu, mgbawa liquefaction).

Na mgbakwunye, usoro a na-enyere aka ịmepụta njikọ nke metallurgical siri ike n'etiti mkpụrụ na mkpuchi.Microalloying n'etiti electrode gbazee na mkpụrụ na-amalite nguzobe nke plasma site na ire ere ikuku, carbonates, carbides na nitrides.

Uru

1.Precision na Accuracy: Electro-spark ọgwụgwọ na-enye ohere maka nhazi ziri ezi na nke ziri ezi nke nkọwa mgbagwoju anya na mgbagwoju anya na-adị n'elu ígwè.Mwepu ọkụ eletrik a na-achịkwa na-emebi ihe ahụ n'ụzọ a na-achịkwa, na-eme ka ịmepụta atụmatụ dị ka obere oghere, oghere, ma ọ bụ ntinye aka na njedebe dị elu.

2.Preservation nke ihe iguzosi ike n'ezi ihe: Otu n'ime uru dị ịrịba ama nke ọgwụgwọ Electro-spark bụ ikike ya iji chekwaa ike na iguzosi ike n'ezi ihe nke workpiece.N'adịghị ka usoro ịhịa aka n'ahụ nke nwere ike iwepụta oke ọkụ ma mee mgbanwe na-achọghị na akụrụngwa akụrụngwa, ọgwụgwọ Electro-spark na-ebelata mpaghara okpomọkụ metụtara ma na-edobe ike nke workpiece na iguzosi ike n'ezi ihe.

3.Complex Geometries: Ọgwụgwọ electro-spark na-enyere aka ịmegharị geometry dị mgbagwoju anya nke nwere ike bụrụ ihe ịma aka ma ọ bụ nke na-agaghị ekwe omume iji usoro igwe eji eme ihe.Ikike ya ịkpụzi atụmatụ ndị dị mgbagwoju anya na-enye ohere maka imepụta ihe ọkpụkpụ, anwụ anwụ, ma ọ bụ ihe ndị ọzọ nwere nhịahụ pụrụ iche na nkọwa dị mgbagwoju anya, na-agbasawanye ohere imewe.

4.No Tool Wear: N'adịghị ka omenala machining ụzọ na-agụnye ịcha ma ọ bụ abrasion, Electro-spark ọgwụgwọ adịghị agụnye kpọmkwem kọntaktị n'etiti ngwá ọrụ na workpiece.N'ihi ya, enwere obere iyi ngwá ọrụ, na-eduga ná ndụ ngwá ọrụ dị ogologo ma belata ụgwọ ọrụ nlekọta.

Nchịkọta

Isiokwu a na-ebutekarị usoro EDM na usoro ịkpụzi, ọ bụghị nanị na-ewebata usoro nhazi ya, kamakwa na-ewebata isi uru nke usoro a.Site na vidiyo dị n'elu, enwere m olileanya na ị nwere ike ịghọta usoro ahụ nke ọma.Ọ bụrụ na ị nwere ajụjụ ndị ọzọ, biko nweere onwe gịkpọtụrụ anyị.

Oge nzipu: Jun-07-2024